APPLICATIONS

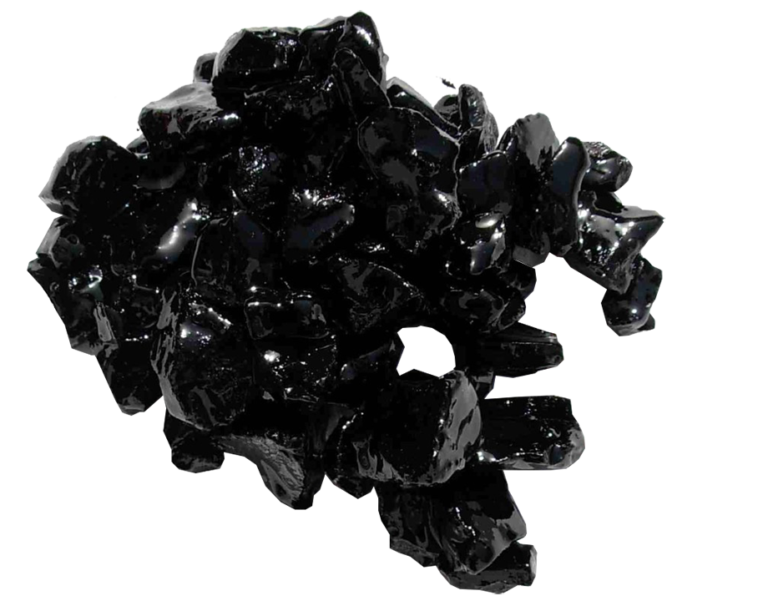

Gilsonite or Asphaltite

Gilsonite is a shiny black, resinous-looking bituminous mineral. It is primarily composed of asphaltenes, hydrocarbons with low oxygen content, and traces of crystallizable paraffin. Its chemical structure provides excellent resistance to corrosion and oxidation, making it ideal for various industrial applications.

Its key properties include:

Hydrophobicity

It does not dissolve in water, alcohols, or acetones, making it highly impermeable.

Solubility in Solvents

It dissolves in Varsol, carbon tetrachloride, and other industrial solvents.

Easy Wettability in Oils

Enhances its dispersion and performance in specialized applications.

Uses and Applications

Oil Well Drilling

Gilsonite is essential in drilling fluids and well cementing, enhancing well stability and operational efficiency.

Its benefits include:

Efficient transport of drilling cuttings.

Lubrication and cooling of the drill bit, extending its lifespan.

Increased well stability, preventing collapses and controlling pressure.

Unlike conventional materials, it improves mud cohesion, seals porous formations, and reduces fluid loss, optimizing the drilling process.

Chemical Products

Used in the production of black varnishes, Gilsonite, when combined with drying oils, resins, and asphalts, creates a versatile product with numerous industrial applications.

Coatings – Applied in brake linings, asphalt tiles, and pipeline protection.

Saturating Compounds – Used for insulated wires and transmission belts.

Impregnated Fabrics & Wood Paints – Enhances durability and finish.

Printing Inks & Photogravure – Provides deep, intense coloration.

Electrical Compounds – Valued for its high dielectric resistance.

Use in Bitumen

Gilsonite is a key component in the production of shoe polishes and dyes, enhancing their quality and performance. Its composition provides a high-gloss finish, uniform coverage, and waterproofing, making it a superior choice in the footwear industry.

Unlike other polishes, Gilsonite adheres more effectively to leather, forming a protective layer that resists moisture, wear, and daily friction. This not only extends the lifespan of footwear but also enhances its appearance and durability under various environmental conditions.

Asphalt Mixes for Paving

and Coatings

Studies conducted by the Federal Highway Administration (FHWA), the Federal Aviation Administration (FAA), the Naval Facilities Engineering Command (NAVFAC), the Michigan Department of Transportation (MDOT), and the Arizona Department of Transportation (AZDOT) show that using Gilsonite in pavement can reduce costs by up to 60% while enhancing asphalt’s resistance to water, oxidation, and UV radiation.

Thanks to its natural oils, Gilsonite helps maintain the flexibility and durability of asphalt, delivering:

30% lower viscosity, making application easier.

30% greater ductility, preventing fractures.

40% higher Marshall stability, improving binder strength.

These advantages extend pavement lifespan by more than five years, significantly reducing maintenance costs.

Use as an

Anti-Oxidation Coating

Gilsonite provides superior protection against oxidation in ships, machinery, and vehicle chassis, while also serving as an effective waterproofing agent for:

Buried concrete pipes and tanks Prevents moisture infiltration and structural damage.

Building foundations and roofs Enhances durability and weather resistance.

Asphalt fabrics and bituminous paints – Improves adhesion and long-term performance.

Wood preservation and treatment – Shields against moisture, decay, and insect damage.

Its exceptional resistance to humidity and corrosive agents significantly extends the lifespan of treated surfaces, making it a reliable choice for industrial and construction applications.

Metal Casting

Gilsonite is used in sand casting to enhance quality and efficiency. It forms a gaseous layer between the molten metal and the mold, preventing sand adhesion and ensuring a smooth finish.

Low Ash & Sulfur Content

Reduces impurities in castings.Fast Volatile Emission

Improves gas release, minimizing defects.High Carbon Content (35-38%)

Enhances casting performance with less material.

These properties make Gilsonite an excellent additive for high-precision castings with improved strength and finish.

GILSONITA PARA CAUCHO

Gilsonite is used as an additive in rubber production, enhancing its properties and overall performance.

Higher Dielectric Strength

Improves performance in electrical applications.Ozone Resistance

Protects elastomers from degradation, extending their lifespan.Reduced Rubber Weight

Enhances flexibility and efficiency across various applications.

Thanks to these advantages, Gilsonite is widely used in industrial rubber products, automotive components, and electrical insulation materials.

Use in the Food Industry

Gilsonite is one of the few minerals approved by the U.S. Food and Drug Administration (FDA) for direct contact with food. Its approval is based on its safety, as it is:

Non-toxic

Non-carcinogenic

Non-mutagenic

Due to these properties, Gilsonite is used in special coatings for food packaging and processing equipment, ensuring safety during handling and storage. Its chemical and thermal resistance makes it ideal for the food industry, where high purity and stability are required.